Space Strategy

Through development of its artificial retina, LambdaVision is pioneering solutions in low-Earth orbit (LEO) that will pave the way for the future of many industries.

LambdaVision’s partnership with Space Tango, which secured >$7.7 million in funding from NASA, and its work with the International Space Station (ISS) U.S. National Laboratory has allowed the company to successfully validate a microgravity manufacturing method for producing LambdaVision’s artificial retina on the ISS. LambdaVision has recently secured two new NASA SBIR grants focused on scaling and machine learning, and the company will continue to explore new frontiers related to in-space manufacturing.

LambdaVision’s artificial retina is one of the first technologies being evaluated on the ISS that has potential for clinical use, and the established microgravity manufacturing processes, quality control methods, and laboratory techniques provide a foundation for future clinical research in space.

WHY SPACE?

LambdaVision aims to utilize LEO to improve manufacturing processes hindered by the influence of gravity. The company is embracing the unique behavior of solutions and thin film assembly in microgravity to improve processes developed on Earth and pave the way for novel innovations.

LambdaVision is leveraging microgravity to improve upon layer-by-layer deposition to produce the first protein-based artificial retina. The layer-by-layer assembly methodology, a process traditionally done on Earth, appears to be improved in a LEO environment where reduced gravity improves homogeneity, stability, and performance of thin films like the protein-based artificial retina.

Space-Based Lab Techniques

The space-based lab techniques and manufacturing methods that LambdaVision is developing to advance the quality and function of its protein-based artificial retina will benefit other companies.

Through 8 missions to the ISS, LambdaVision and implementation partner, Space Tango, have developed and validated space-based lab techniques and manufacturing methods. The company has consistently met the goal of manufacturing multiple 200-layer artificial retina thin films in microgravity. The collaborative effort between LambdaVision and Space Tango has led to the completion of a series of proof-of-principle microgravity experiments that have established a foundation for producing artificial retinas using a LEO platform.

The missions have demonstrated reproducible hardware performance in both a terrestrial and microgravity environment, and the CubeLabs have a proven tech stack with good control and automation. Beyond these technical milestones, LambdaVision’s commercialization and good manufacturing practice (GMP) strategies have advanced, demonstrating the feasibility of manufacturing a drug or therapy using a LEO platform. The 9th mission to the ISS was in Q1 of 2024.

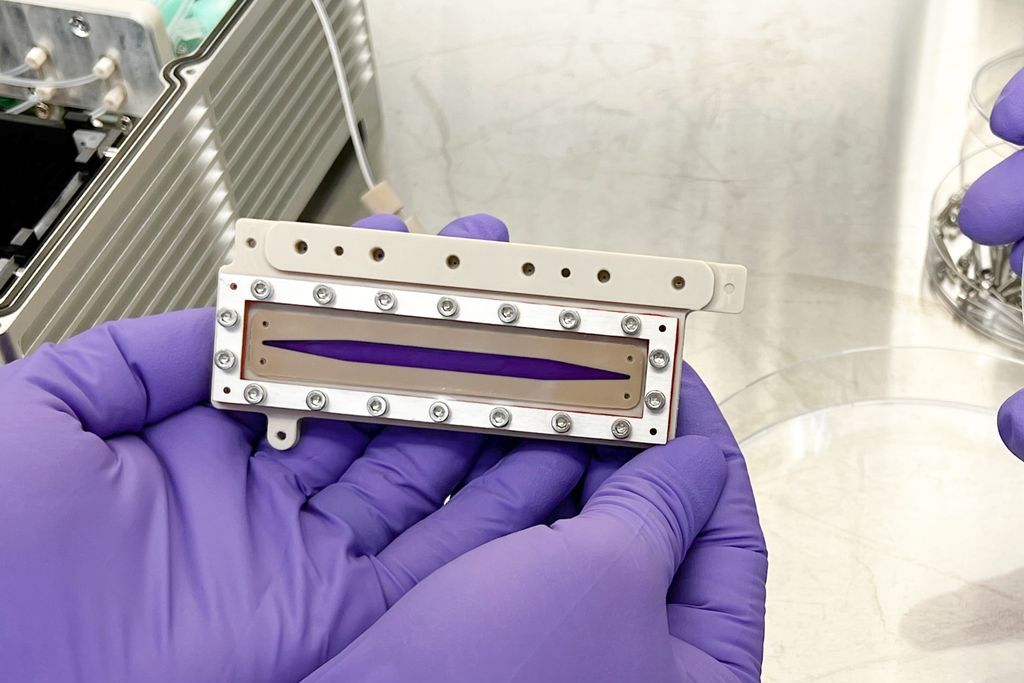

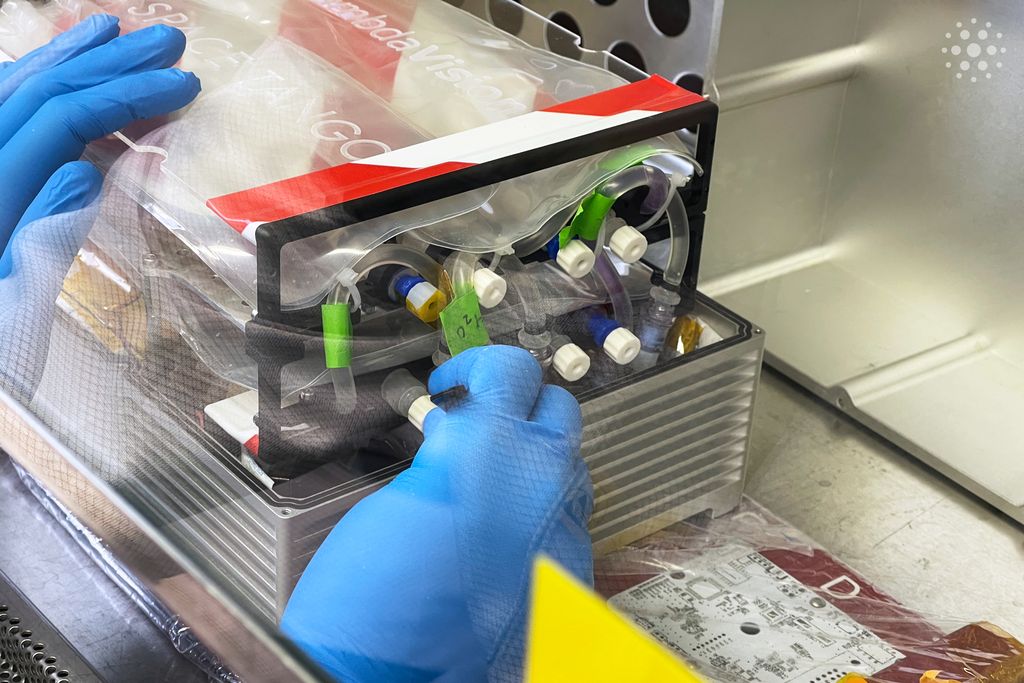

From left to right: Artificial retina thin film development chamber, SpaceTango and LambdaVision CubeLab, Interior of CubeLab containing optimized and automated hardware for layer-by-layer deposition development of LambdaVision’s artificial retina in microgravity.

Accelerating the process for others in LEO

LambdaVision’s layer-by-layer technology has important commercial potential in microgravity for applications in bacteriorhodopsin-based solutions, as well as in other clinical and technological arenas.

Bacteriorhodopsin-Based Applications

- Artificial Retinas

- Photovoltaic Energy Production

- Optical Pattern Recognition

- Associative Processors/Neural Networks

- Chemical/Environmental Toxin Detection

Additional Opportunities

- Drug Delivery Systems

- Biosensors/Bioprinting

- Tissue Engineering, Bone Grafts

- Cell Assemblies for Transplantation

- Products Requiring Good Manufacturing Practices

LambdaVision’s commercial efforts in microgravity will demonstrate that it is feasible to manufacture a drug or therapy using a LEO platform. These achievements will inspire new research and commercial product development that will build a thriving LEO economy.